Machine

-

Hot

PVC Pipe extrusion line

PVC pipe extrusion machine has features of low energy consumption,high output,stable running

Email Details

etc.

The standard PVC pipe extrusion machine include:material feeder,SJSZ series conic twinscrew extruder,mould,vacuum calibration tank,spray cooling tank,haul-off,cutter,stacker.It is mainly used in producing various diameters and wall-thickness of PVC pipes for agricultureand constructional plumbing,electrical conduit etc. -

Hot

plastic crusher

SWP series crusher is mainly used to crush waste or unqualified plastics such as block,bar,pipe,sheet,plate and profile.

Email Details -

Hot

PC,PP,PE Plastic Hollow Plate/Board Extrusion Line

Applicant:

Email Details

PC hollow board is mainly for construction,Such as

1)Lighting ceiling for Office buildings,halls,shopping malls,sports stadiums,public facilities

2)Rainshed for the station,parking lot,pavilion,rest hall corridor

3)Highway and city road noise barrier.

PP hollow board is mainly used for:

1)with two processing performance,light,high strength,Good environmental

performance,dampproof features,so can be processed into a turnover box,packing box and so on.

2)is widely used in Electronic,electrical appliances,bags,machinery,postal,Food,medicine,pesticide and advertising decoration. -

Hot

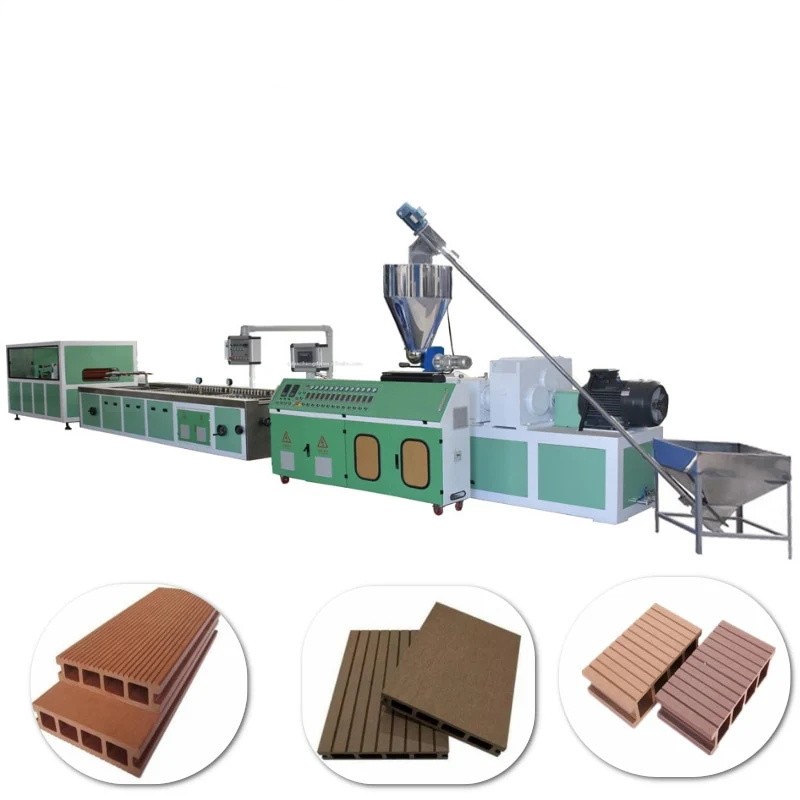

WPC decking, fencing, wall cladding extrusion line

WPC decking, fencing, wall cladding production line is mainly composed of feeder, twin screw extruder, calibration table, cutting machine, stacker.

Email Details

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola.

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold, we can equip co-extrusion system and online 3D embossing device for making WPC products in high quality with wooden grain, the line also equipped with online cutting device. -

Hot

PPR/PERT Pipe extrusion line:

This production line is mainly used for the production of pipe material with PP-R resin as rawmaterial,but also suitable for the production of pipe material with PE-RT,Pb,PE-X resin as rawmaterial.

Email Details

Application:

1.Man-machine interface operation,high degree of automation.

2.Using special screw,plasticizing effect is good.

3.Adopt compound spiral head,effectively remove material memory function.

4.Vacuum shaping and constant temperature control eliminate the stress of pipe material.

5.Adopt co-extrusion machine head and increase the standard color line of pipe material.

6.Large extrusion capacity,low melt temperature,melt temperature uniform.

7.A wide range of material processing. -

Hot

PE Large-diameter winding pipe prodution line

PE large-diameter winding pipe production line is composed of a special-shaped pipe extruder,awelding extruder,a winding forming machine,a cutting machine,and related auxiliary machines.

Email Details

Features:

1)It has the advantages of large production volume,high production efficiency,stable operation,high pipe ring stiffness,small unit meter weight,excellent creep resistance,convenientconnection and economic construction.

2)The extruder adopts a specially designed high-efficiency single-screw extruder.The screw andbarrel have unique structure,large output,low energy consumption,excellent plasticization,reasonable mold structure,dual-machine combined feeding and rotating molding,and theconcept is exquisite.unique design.

3)Advanced PLC computer control system can be adopted,which is easy to operate and stableand reliable in action.It adopts double-stage pressure-reducing screw,with special componentsto promote mixing and plasticization,high torque,and high temperature control accuracy.Adopting compound head,dual machine united feeding,spiral rotation forming,high-efficiencycompounding process,to ensure the high quality of the product.

Uses:

Pipes are mainly used for drainage pipes in industries such as industry,pharmaceuticalfactories,municipal administration,and construction engineering. -

Hot

SMP series Plastic Pulverizer

This machine can be used for powder processing of polyethlene (PE),polyvinylchloride (PVC),polypropylene (PP),polystyrene (PS),ABS,nylon and other materials.

Email Details

Features:

1.Adopting new grinding disc design,high output and strong wear resistance.

2.The use of newly designed professional bearings ensures efficient grinding and collision andgreatly saves mechanical operation time.

3.Easy to install and maintain,it can be cleaned by opening the door cover.

4.The milling process is fully sealed and there is no dust leakage. -

Hot

SRL series plastic mixer

The mixing unit is suitable for materials mixing and coloring in plastics,rubber,daily chemical andother industries.It is an ideal equipment for producing plastic plates,plastic tubes,profiles,andbiodegradable plastics.

Email Details

Features:

1.Mixed materials are made by negative pressure mixed principle

2.The electrical instruments are all well-known imported appliances

3.High degree of automation and speed mixing

4.The blade was made by stainless steel pressure and passed the static and dynamic balance test

5.The cooling paddle adopts foreign advanced spiral mixing structure,the whole container has nodead corners,the cooling speed is fast,and the discharge is clean.Technology information: -

Hot

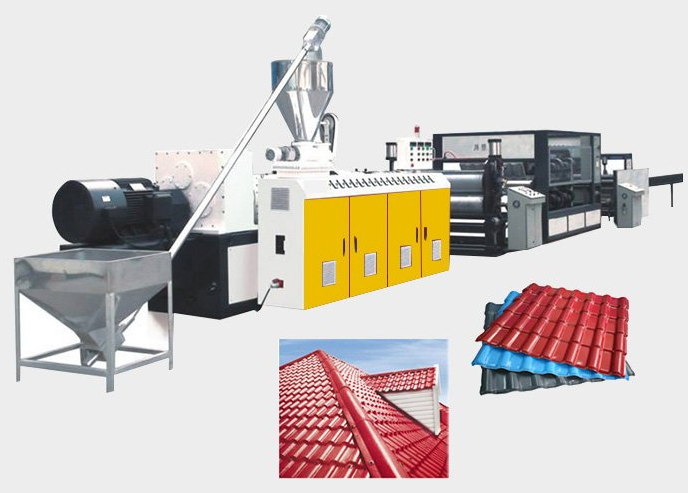

PVC glazed /spanish corrugated roof sheet extrusion line:

Scope of application:

Email Details

It is suitable for roofing fields such as flat to slope,villas,mobile houses,garden attics,etc.