PE Large-diameter winding pipe prodution line

- JOINZEAL

- Qingdao

- 45-55days

- 200lines one year

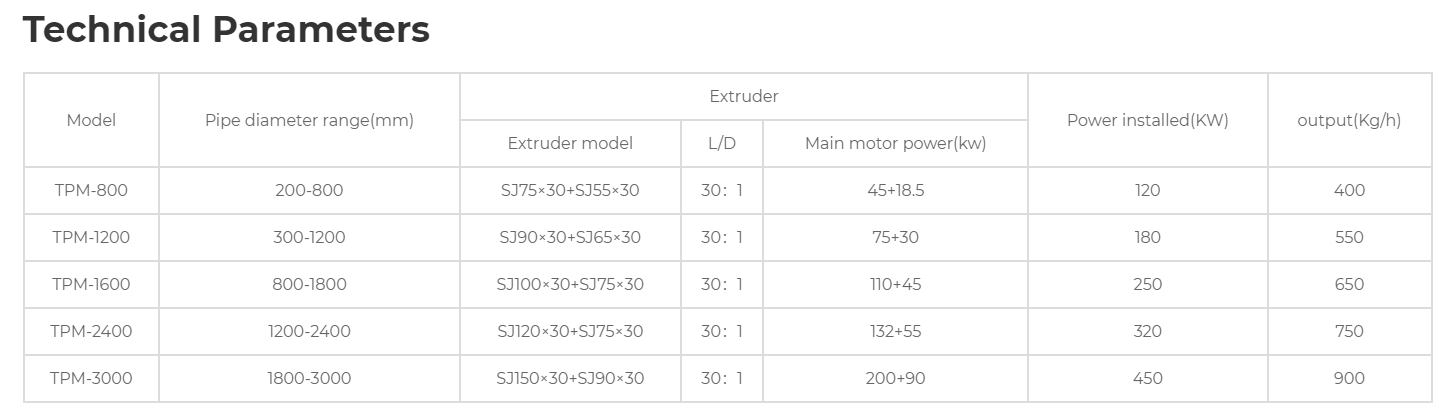

PE large-diameter winding pipe production line is composed of a special-shaped pipe extruder,awelding extruder,a winding forming machine,a cutting machine,and related auxiliary machines.

Features:

1)It has the advantages of large production volume,high production efficiency,stable operation,high pipe ring stiffness,small unit meter weight,excellent creep resistance,convenientconnection and economic construction.

2)The extruder adopts a specially designed high-efficiency single-screw extruder.The screw andbarrel have unique structure,large output,low energy consumption,excellent plasticization,reasonable mold structure,dual-machine combined feeding and rotating molding,and theconcept is exquisite.unique design.

3)Advanced PLC computer control system can be adopted,which is easy to operate and stableand reliable in action.It adopts double-stage pressure-reducing screw,with special componentsto promote mixing and plasticization,high torque,and high temperature control accuracy.Adopting compound head,dual machine united feeding,spiral rotation forming,high-efficiencycompounding process,to ensure the high quality of the product.

Uses:

Pipes are mainly used for drainage pipes in industries such as industry,pharmaceuticalfactories,municipal administration,and construction engineering.

PE large-diameter winding pipe production line:

PE large-diameter winding pipe production line is composed of a special-shaped pipe extruder,awelding extruder,a winding forming machine,a cutting machine,and related auxiliary machines.

Features:

1)It has the advantages of large production volume,high production efficiency,stable operation,high pipe ring stiffness,small unit meter weight,excellent creep resistance,convenientconnection and economic construction.

2)The extruder adopts a specially designed high-efficiency single-screw extruder.The screw andbarrel have unique structure,large output,low energy consumption,excellent plasticization,reasonable mold structure,dual-machine combined feeding and rotating molding,and theconcept is exquisite.unique design.

3)Advanced PLC computer control system can be adopted,which is easy to operate and stableand reliable in action.It adopts double-stage pressure-reducing screw,with special componentsto promote mixing and plasticization,high torque,and high temperature control accuracy.Adopting compound head,dual machine united feeding,spiral rotation forming,high-efficiencycompounding process,to ensure the high quality of the product.

Uses:

Pipes are mainly used for drainage pipes in industries such as industry,pharmaceuticalfactories,municipal administration,and construction engineering.